Environmental and social responsibilities

A sustainable and responsible refinery

An alumina refinery generates real, albeit limited, constraints (non-SEVESO site: no risk of explosion). These constraints, inherent to its mature process, mainly concern the production and especially the storage and reuse of bauxite residues, its significant consumption and industrial water discharges, as well as its significant energy consumption.

As our project is a “greenfield” project, minimizing environmental impacts was integrated from the design phase and into each component (infrastructure, studies, operations plan and interactions).

Our environmental and social impact assessment study has been voluntarily aligned with the most demanding standards (the Equator Principles and the IFC standards) when they are more restrictive than local legislation.

Drawing on 131 years of operation at its Gardanne site (France), a longevity that has exposed it to the full spectrum of regulatory and societal changes, whether anticipated or experienced, Alteo leverages this proven track record, marked by situations that were sometimes challenging to implement. It is precisely this mastery of these challenges that positions the site as a global benchmark. Its expertise extends beyond the flawless execution of the complete refining process, focusing above all on the management, control, and proactive mitigation of environmental and societal constraints.

All of these challenges are integrated into an approach aimed at ensuring sustainable and responsible production, backed by an operational heritage of over a century.

1. Tailing operation and management of bauxite residues

Recognized operational expertise in the storage of inert refining waste , while optimizing the footprint, controlling the risk of infiltration into aquifers and limiting dust emissions. This expertise has been implemented for more than 10 years in France, located in the heart of tourist Provence.

In terms of process water treatment and bauxite residue management, the implemented solutions will alow for the discharge of only clean water and the environmentally friendly storage of neutralized residues.

2. Recycling of Refinery waste

Alteo was the pioneer in the recycling of this bauxite waste, also having recognized experience and know-how in the implementation of cutting-edge waste recovery methods (road underlays, products for the construction industry, waterproofing, post-mining treatment).

These efforts, a real challenge for the entire profession, will continue within the framework of ARG in Guinea.

Our project integrates waste minimization objectives , favoring reusable or recyclable packaging.

3. Treatment and Water balance

Operating in an environment where water stress is permanent, Alteo’s teams have developed recognized expertise in the rational and limited use of water resources , accompanied by know-how in the treatment of discharges and more generally the optimization of the process’s water balance to limit withdrawals from the natural environment.

The consideration of these constraints and their compensations linked to the process are closely worked on within the framework of the environmental studies in particular which were entrusted to the specialized study office Artelia. We made the methodological choice to respond not only to all the rules and good practices of the profession (GISTM, internal guides) but also the sectoral roadmaps (alumina) of the EIB and the Australian Government, and finally the Guinean standards reinforced by the IFC standards and the Equator Principles.

These choices are essential for the project and its partners, in order to ensure and guarantee that all technical decisions meet the highest current standards.

CO2

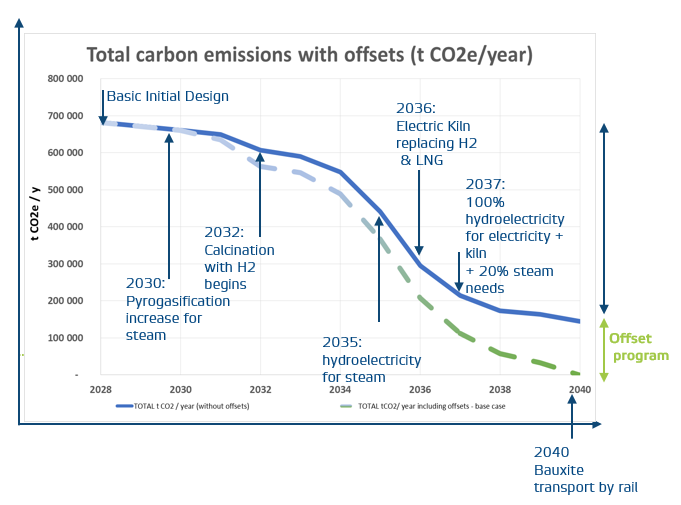

Our energy and CO2 objective is to achieve exceptional results in reducing greenhouse gas (GHG) emissions, with a target of neutrality by 2040.

According to the carbon intensity calculations carried out on the basis of the reference energy scenario, the following results were obtained:

- Calcined alumina (as Al2O3): 0.760 t CO2eq/t Al2O3, i.e. -45% emissions compared to the IAI global average.

- Hydrated alumina (as Al2O3): 0.545 t CO2eq/t of hydrate, i.e. -17% compared to Alcoa (best global reference )

This makes the ARG project the most efficient project in the world in terms of GHG (Eurosource 2023 and IAI 2023 data).

Thanks to Alteo’s experience at its Gardanne site, a decarbonization plan has been established, aiming for carbon neutrality by 2040.

This plan is based on:

- Optimized process design,

- Industrial solutions developed in Gardanne (e.g.: RMV type evaporation concentrator, KX exchanger attack, energy-based design, etc.,

- Solutions and energies under development (H2, electric furnaces),

- Stakeholders in hydroelectric and solar energy (project development in progress),

- As well as a compensation program (mangroves on secure land, soil sequestration – soil regeneration techniques) .

An ambitious and also essential societal approach

The area chosen for the refinery development currently occupies the villages of Kabata and Kassoupo (potentially Taressa), bringing together 250 households. Based on the experience of our Gardanne industrial site, we have chosen to secure a vast area of 1200 ha including the 250 ha necessary for the operations as a whole but also a glacis zone to limit the nuisance to local residents.

The site was chosen with the need to minimize the impact on our future communities in mind. Our impact assessment will be conducted to the highest standards and will be audited by independent experts.

This involves the relocation of these homes and families. These operations, in accordance with Guinean and IFC regulations, have been entrusted to a local consultancy firm, SERES (SEES), acting under the supervision of Artelia. The necessarily long and detailed inventory operations are underway and are fully part of the environmental and societal impact studies, integrating not only the relocation of affected communities, but also all the initiatives and rules to be implemented to promote employment and the emergence of activities for local development, in close collaboration with the authorities and civil society.

Our community teams are on site daily to develop and facilitate an inclusive and quality dialogue.

Training programs were launched from the outset of the project to ensure the training of the necessary qualified personnel. Partnerships were established with the Ministry of Education and UNIDO to build capacity for appropriate training.

Health and Safety

All our operations is carried out in accordance with the highest health and safety standards.

Ethics and Business Conduct

All our interactions with third parties are conducted professionally. We do not tolerate any acts of corruption or fraud.

We do treat all people equally and with respect. We do not tolerate any form of discrimination.